Process

Efficient businesses can reduce costs, improve profitability, and generate lasting sustainable processes. A key focus of this pillar will be continuing to embed the continuous improvement mindset across the business to deliver these incremental improvements which together make us more efficient.

Our focus area

Continuous improvement

Maximise operational efficiencies for environmental benefit

Continuous Improvement

We have been building Continuous Improvement into everyday culture and everything we do. This is a core element of our strategy and key to the delivery of many of our targets including delivery of carbon emission reductions. Our aim is to empower every employee, across functions and at every grade, to consider small incremental or transformative improvements to their everyday.

If we truly embed a CI enterprise we will nurture a culture where everyone

is accountable and generate benefits that will make our business stronger for the future including reducing environmental impact through improved use of resources and encouraging collaboration with suppliers and customers which generate improvements across our value chain.

Embedding a CI culture can help us reduce our environmental impact

Journey to net zero

In 2021 we committed to being net zero by 2045 by achieving an absolute reduction in scope 1 and 2 carbon emissions. In 2023 we set a medium-term target to reduce scope 1 and 2 emissions by 25% by 2028 (as a percentage of revenue).

Our strategy to meet our medium-term target is to reduce our carbon emissions through improving efficiencies.

Resource use

CI helps us to identify wasteful processes, encourages everyone to seek opportunities to reduce waste in all its forms, and become more efficient with the resources we use.

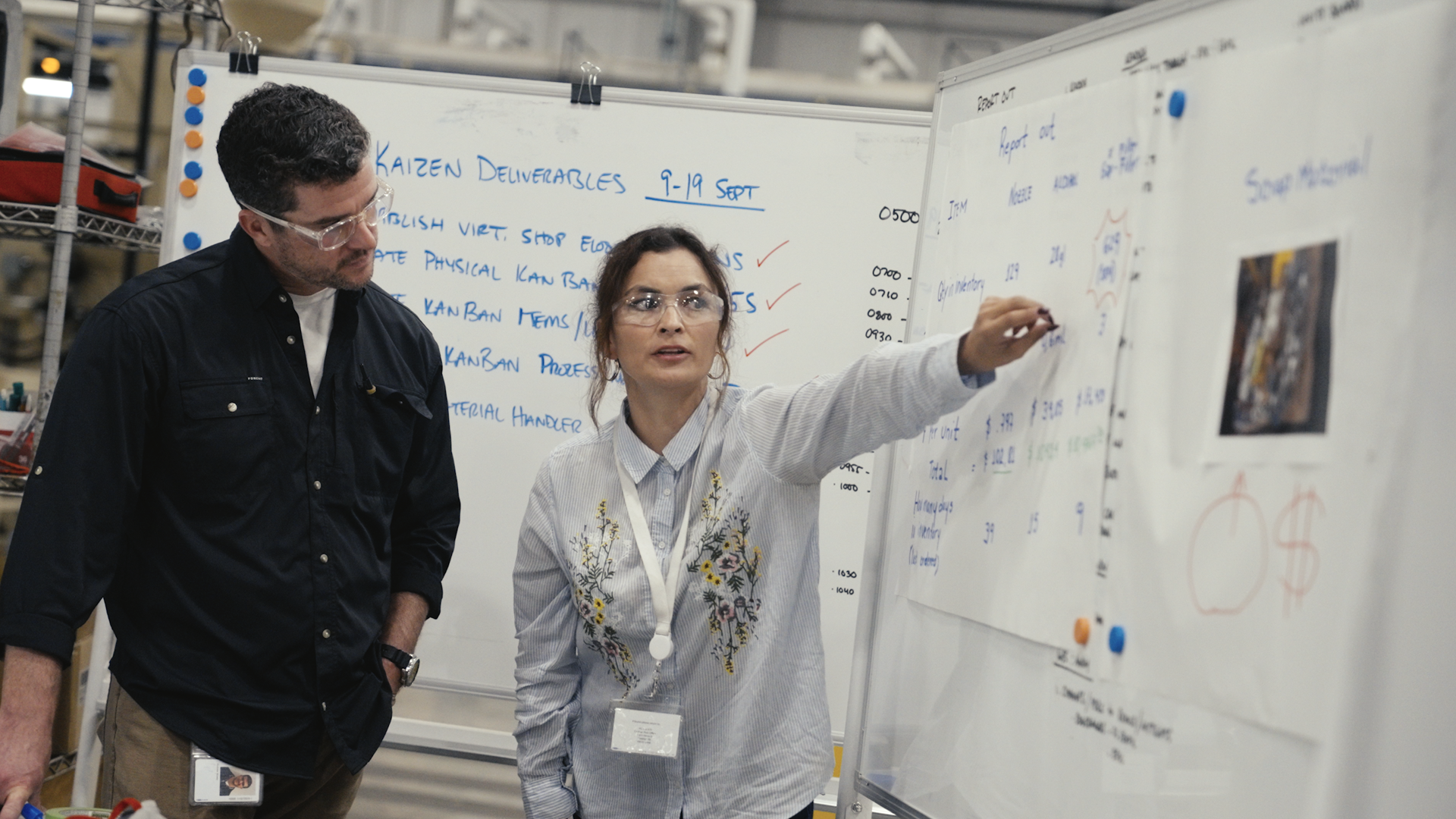

Undertaking frequent Kaizens has helped us to improve our operational

KPIs including to reduce our scrap rate.

Certification

We use environmental management systems to monitor, control and continuously improve environmental performance across our sites.

We have achieved ISO14001 accreditation, at three of our five sites. This achievement demonstrates that management and employees remain engaged on implementing and maintaining best environmental practices.

Measuring Environmental Impact

Across our sites we track environmental data including energy use, waste generated in our operations and water use which we report on. We use this information to set targets and report on our performance.

See our environmental data in our Annual report.

For more information on the preparation of our annual greenhouse gas emission data and environmental data, see our Methodology Statement.

find out more

Working with our value chain to support Continuous Improvement

CI doesn’t just stop at the gates to our manufacturing sites. To get the full benefit of CI we must work with our supply chain and customers, which can generate improvements for all stakeholders. Collaboration is crucial as we move our operations push to pull.

Moving from push to pull means we are only making what the customer actually needs, so that we only make products once there is an order. We set a ‘beat’ of assembly which matches the expectations of our customer. This will result in improved lead times for our customer and reduced WIP in our own operations. In addition, by pulling from upstream processes rather than trying to push materials that the downstream cannot use we also reduce inventory. Collaborating with supply chain with this mindset has helped us identify opportunities to optimise transportation and packaging of materials.

Another way we seek to encourage collaboration is through our supplier sustainability questionnaire which includes environmental social and governance questions. We hope to identify more initiatives where we can partner to collectively reduce environmental impact and become more efficient.